polycarbonate rod impact test|taylor impact test : private label High-speed photographic sequence of a polymer cylinder undergoing classic Taylor impact from right to left. Two high-speed photographic sequences are presented of (A) the .

webWatch the fourth episode of South Central Baddies, a reality show about the lives and challenges of young people in South Central Los Angeles. The show features interviews, challenges, and drama with the baddies and their families.

{plog:ftitle_list}

The latest tweets from @eugrazimourao

taylor impact test plasticity model

how polycarbonate should and should not be used. Notched Izod impact testing is an experimental method to quantify the energy absorbed by the polymer during the adverse .

taylor impact test

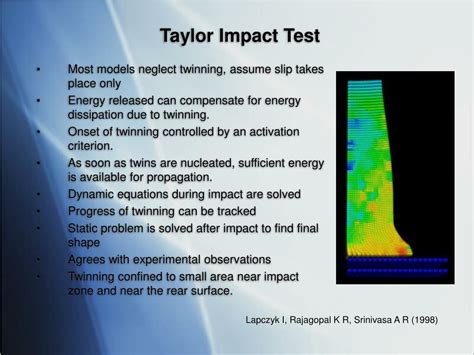

Taylor impact test is the simplest experimental approach for characterizing plastic behaviour of metals under high strain rate (up to 10 5 s − 1). Herein, a cylindrical rod is .In this paper, Taylor impact exper-iments were conducted to examine the mechanical behavior of polycarbonate (PC), under conditions of high strain rate ( 105 s 1) and inhomogeneous .

This study presents detailed images, fracture energies, and time durations of the deformation and failure processes actively occurring during the Notched Izod testing of 3.23mm and 6.35mm . Basically, the Taylor impact test measures the impact yield stress through large non-uniform plasticity in deformed specimens and has been widely expanded, such as . High-speed photographic sequence of a polymer cylinder undergoing classic Taylor impact from right to left. Two high-speed photographic sequences are presented of (A) the .

The impact of a flat-ended cylindrical rod onto a rigid stationary anvil, often known as the Taylor impact test, is studied. An axisymmetric model is developed to capture the deformation behaviour of the rod after impact.

The Izod impact test fixes one end of a notched specimen in a cantilever position by means of a vice. A striker on the arm of a pendulum or similar energy carrier then strikes the specimen. The energy absorbed by the . In this study, izod impact test has been simulated to analyze the mechanism of impact modifier reinforced Nylon 6. Computational results were compared for numbers and .

polycarbonate test notched

polycarbonate strain rate

with lawn mower compression test

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

Polycarbonate Material Data Sheet General Purpose, Glazing Grade . . Izod Impact Strength, Notched @ 0.125" Izod Impact Strength, Unnotched @ 0.125 . Test Method ASTM D 792 ASTM D 542 ASTM D 1003 ASTM D 1003 ASTM D 1003 ASTM D .

Polycarbonate PC 1000 is a mechanical grade material available in several sizes of rod and sheet. When polished, it has a light transmittance of approximately 88% and is stress relieved making it ideal for close tolerance machined parts. .Boedeker offers Polycarbonate Plastic Grades in Sheet, Rod & Tube, in Stock, Cut to Size, Same Day Shipping, Polycarbonate Machined Parts & Tech. Support 1-800-444-3485 Toggle navigation

Machine grade polycarbonate (PC) is a transparent amorphous thermoplastic which offers very high impact strength and high modulus of elasticity. The material has a 290°F (145°C) heat deflection temperature at 264 psi, absorbs very little moisture and resists acidic solutions. Polycarbonate derives its incredible impact strength from the molecular structure of the plastic. . acrylic is generally the more affordable option compared to polycarbonate. Acrylic sheets and rods can cost 20-50% less than comparable polycarbonate materials. . budget, and fabrication requirements. Test any unsure applications. With an .

Polycarbonate Sheet, Rod, & Tube Lightweight and virtually unbreakable clear plastic for glass replacement, glazing, signage, and more. Polycarbonate is a transparent and virtually unbreakable thermoplastic with outstanding impact resistance, strength, and durability. It has similar optical properties to glass at a much lower weight.D1709-24 Standard Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method . Mechanical Properties. . D3916-22 Standard Test Method for Tensile Properties of Pultruded Glass-Fiber-Reinforced Plastic Rod . D2343-17(2023) Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in . If the rods are made of the same material and of the same diameter, neither will indent the other. So rod-on-rod impact can be considered equivalent to the impact of a single rod with an ideally rigid surface. The technique (later named the symmetric Taylor impact test) was first reported in the 1980s in Erlich et al. (1982) and Erlich (1985).

Taylor impact test is the simplest experimental approach for characterizing plastic behaviour of metals under high strain rate (up to 10 5 s − 1).Herein, a cylindrical rod is impacted upon a rigid stationary anvil and the dynamic yield strength is estimated by comparing the experimentally obtained rod deformation with its theoretical counterpart.Note: The result of the impact test is reported in energy lost during the impact per unit of specimen thickness (such as ft-lb/in or J/cm). Test results, especially in Europe, may be reported as energy lost per unit cross-sectional area (J/m 2 or ft-lb/in 2). What are the test methods to measure toughness?Choose from our selection of polycarbonate rods, including metal, plastic, and more. In stock and ready to ship. BROWSE CATALOG. Abrading & Polishing; Building & Grounds; Electrical & Lighting; Fabricating; Fastening & Joining . Impact Resistant. Moisture Resistant. Nonconductive. Slippery. Thermally Stable. ID. 1 / 8 " 1 / 4 " 3 / 8 " 1 / 2 .

The impact of a flat-ended cylindrical rod onto a rigid stationary anvil, often known as the Taylor impact test, is studied. . the radial velocity is zero in the un-deformed part of the rod. In the plastic region, the radial velocity, which causes the transverse deformation (bulging), is symmetric with respect to the longitudinal axis .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .Polycarbonate plastic, often referred to by the abbreviation PC, is manufactured by Ensinger in standard stock shapes for machining parts and is extruded in plate (or sheet), rod and tube. PC plastic is an amorphous thermoplastic with good electrical properties combined with superior impact strength and moderate chemical resistance.

Title: Physical Properties for Machine Grade Polycarbonate Rod Description: Physical, Mechanical, Electrical and Thermal Typical Properties. Published: 1/29/2009 Last Edited: 1/10/2023 2 users found this article useful.

Polycarbonate rod is a semi-transparent thermoplastic that exhibits high impact resistance, good machinability, and excellent electrical properties. In addition, its low moisture absorption rate and good chemical resistance make it an extremely versatile engineering material and allows for its use in a multitude of industrial applications .

Polycarbonate machine grade rods provide a combination of toughness, heat and flame resistance, and dimensional stability. Order polycarbonate machine grade rods today from Acme Plastics. . •Exceptional high impact strength over wide temperature range •Excellent combo of toughness, heat and flame resistant, and dimensional stabilityThis rod has high impact strength, good machinability, and dimensional stability. It is low water absorbtion, with thermal properties from -40°F to 270°F. It is good for high voltage switches, electrical insulators and connectors, and replacement for metal components where wear and impact are important.

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.Clear polycarbonate sheets and rod provided by Interstate Plastics is a lightweight, virtually unbreakable plastic with extreme impact resistance. Polycarbonate is also known by brand names including PolyGal, and Makrolon®.Rod; Tube; Gar-Dur® UHMW This chart shows the physical properties of Gar-Dur®. It should be noted that Gar-Dur® UHMW has the highest impact resistance of all thermal plastics. Gar-Dur® has outstanding low-temperature impact strength plus high energy absorption. As an example of toughness, Gar-Dur® UHMW is used in mallet faces and hammer heads.

Notch test: 20–35 kJ/m 2: . rods and other profiles including multiwall; extrusion with cylinders . Decorative bezels and optical reflectors are commonly made of polycarbonate. Its low weight and high impact resistance have made polycarbonate the dominant material for automotive headlamp lenses. However, automotive headlamps require outer .Polycarbonate Rod is a transparent thermoplastic that exhibits high impact resistance, good machinability, . Polycarbonate Rod has excellent dimensional stability and maintains good strength and stiffness over a wide temperature range. . Test Conditions Test Method Unit Typical Values; Density: SO 1183-1: g/cm3: 1.2:Tuffak® (formerly Makrolon® GP) – General Purpose Polycarbonate Sheet~ UV Stable and Excellent for high impact and glazing applications. Tuffak® (formerly Makrolon® GP-V) – UL rated General Purpose Polycarbonate Sheet ~ UV Stabilized and UL 94 V-2 at .060” thickness, UL 94 V-0 at .220” thicknessClear Impact-Resistant Polycarbonate Rods and Discs. At only half the weight of glass, polycarbonate maintains excellent impact resistance across a wide temperature range. It's comparable to Lexan, Hyzod, Tuffak, and Makrolon. Clear .

Polycarbonate rod is a high impact plastic with outstanding dimensional stability and optical clarity.It provides good electrical and heat resistance properties. It is easy to machine, weld and bond and can also be formed. Polycarbonate rod has good resistance to most inorganic chemicals, oils and dilute acids/alkalis.

notched izod impact testing

Tabela FIPE Chevrolet Onix. Tabela FIPE de anos de carros Chevrolet Onix. Selecione um ano da lista abaixo para ver todos os valores de carros Chevrolet Onix. Consulte a Tabela FIPE Chevrolet Onix 2016 atualizada em Fevereiro de 2024 com preços de .

polycarbonate rod impact test|taylor impact test